TBG MOLD SOLVE ALL

DIFFICULTIES OF

TOOLING AND MOLDING FOR YOU

OUR MOLD MAKING PROCESS

“TBG mold apply our works, our communications, our warranties and our ability to meet our customer’s needs. The trust, relationships and value from our customer is our pursuit.”

01

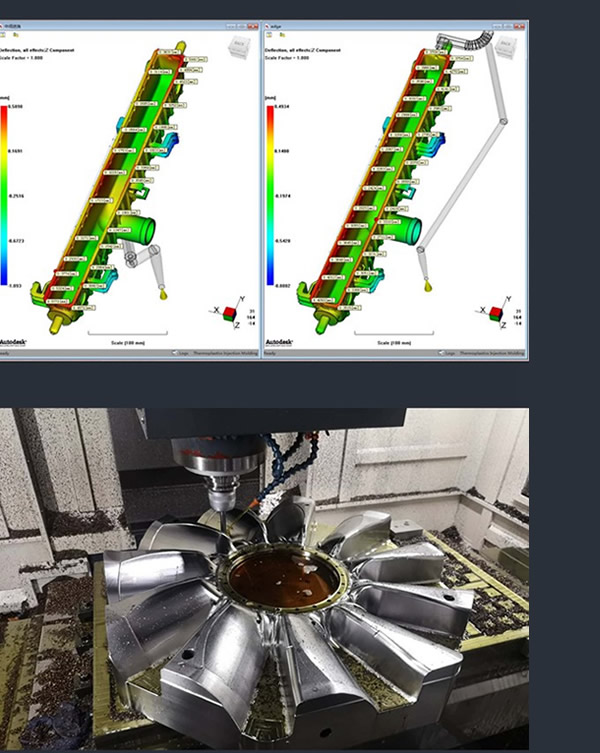

MOLD DESIGN

Mold design is the basis of mold manufacture, the soul. TBG Mold has more than 7 years of experience in export mold designers, we provide DFM, Mold 3D drawing, mold flow analysis report to customer during project design stage.

02

MOLD PROCESSING

Mold making is the heart of our business. TBG Mold carry out the following machining processes for mold production: CNC EDM, wire cutting, polishing.

03

QUALITY CONTROL

TBG Mold uses CMM, GOM scanning , Blue scanning to reliable steel inspection data and molded part inspection data to ensure you are getting a high value, high-quality product.

04

MOLD ASSEMBLY

Our mold assembly in house, we have more than 10 years of mold assembly workers, for your mold escort.

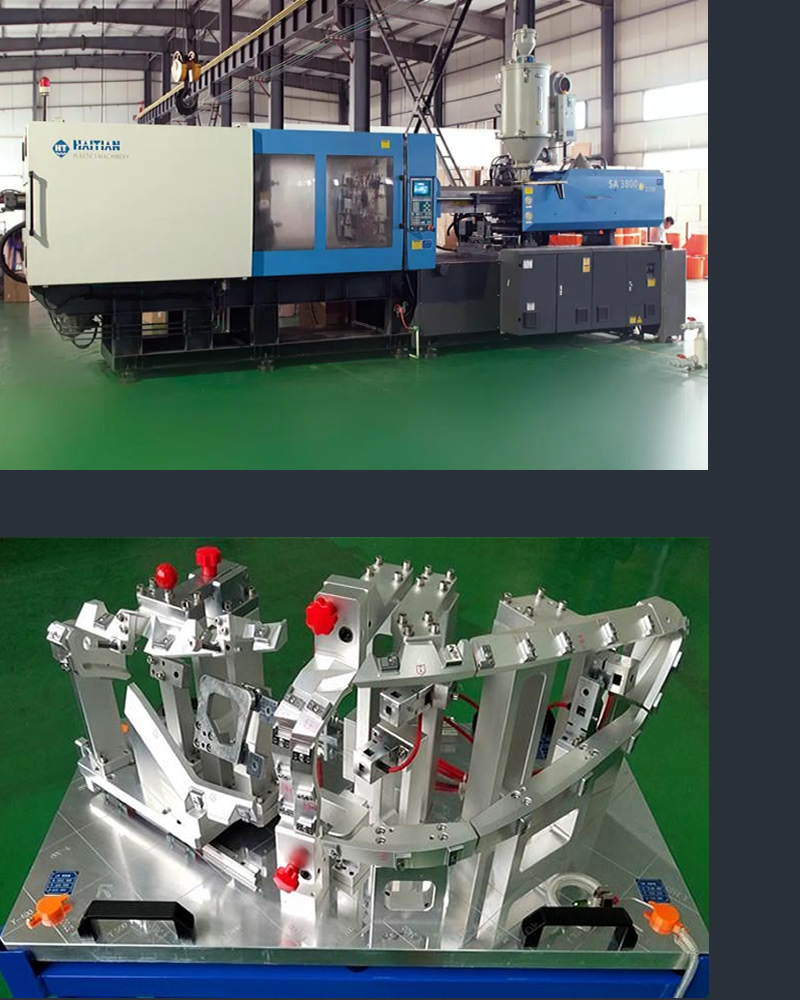

05

MOLD TRIAL

TBG has different tonnage and type machine to support the mold trial in China. We can support 60 T ~2800 T , 1k and 2k machine for mold trial and serial production.We provide mold trial report, part measurement report and mold trial video to you to know mold trial details.

06

FIXTURE MAKING

TBG Mold can manufacture inspection fixtures for your molded parts.

07

AFTER SALES SERVICE

TBG Mold stands behind the quality and workmanship of their tooling 100%. We have after sales partners in some European and American countries.

total quality + deep experience